Hey there, folks! Let me tell ya somethin', we're about to dive into the world of shaft balls and uncover everything you need to know. Whether you're here because of curiosity or because you're dealing with some mechanical issues, this article's got you covered. So buckle up, because we're about to get into the nitty-gritty of what makes these little fellas so important.

Now, when we talk about shaft balls, we're not just throwing random words around. These components play a crucial role in various machines, and understanding them can save you a ton of trouble down the line. So, if you've ever wondered what they are or how they work, you're in the right place.

Before we get too far ahead, let's establish something important: we're here to break it down in a way that's easy to understand, even if you're not a mechanical engineer. Think of this as a casual chat over coffee, where we make sense of technical jargon and turn it into everyday language. Sound good? Let's go!

Read also:Tina Jaxa Set To Star In Exciting New Historical Series

What Exactly Are Shaft Balls?

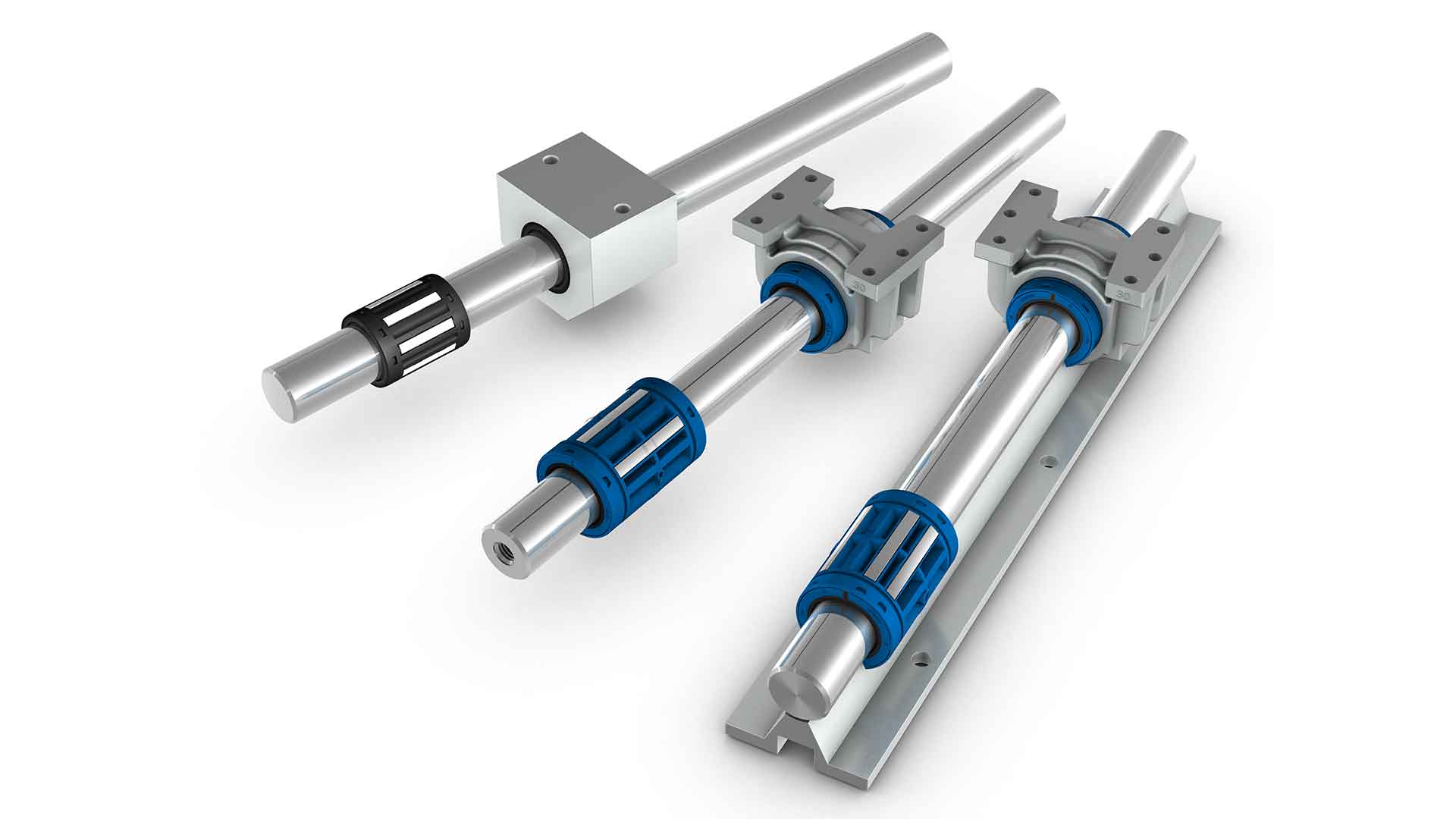

Alright, first things first. Shaft balls are small, spherical components often used in machinery to reduce friction and wear between moving parts. They're kinda like the unsung heroes of the mechanical world, quietly doing their job without much fanfare. But don't let their size fool you; they pack a punch in terms of functionality.

These balls are typically made from materials like steel, ceramic, or even plastic, depending on the application. The choice of material depends on factors like load, speed, and environmental conditions. For instance, if you're dealing with high-temperature environments, ceramic balls might be the way to go. Got it?

Why Are Shaft Balls So Important?

Here's the deal: shaft balls are essential because they help machines run smoother and last longer. Without them, friction would cause excessive wear and tear, leading to costly repairs or replacements. Think about it like this – if your car's engine didn't have proper lubrication, it'd be a disaster waiting to happen. Same goes for these little balls.

They also contribute to energy efficiency. By minimizing friction, machines can operate more efficiently, which translates to cost savings and better performance. So, if you're looking to optimize your equipment, paying attention to these components is a smart move.

Applications of Shaft Balls

Now that we've covered the basics, let's talk about where you'll find shaft balls in action. These little guys are everywhere! From industrial machinery to everyday household appliances, they're hard at work making things run smoothly. Here's a quick rundown:

- Automotive Industry: Ever wondered how your car's transmission works so seamlessly? Shaft balls play a significant role in reducing friction and wear in gears and bearings.

- Manufacturing Equipment: In factories, these components ensure that conveyor belts and assembly lines operate without a hitch.

- Home Appliances: Your trusty washing machine or refrigerator? Yep, they've got shaft balls too, keeping things cool and spinning just right.

Shaft Balls in Everyday Life

Believe it or not, shaft balls are closer to your daily life than you might think. Take your blender, for example. Those blades are spinning at high speeds, and without proper lubrication and support from shaft balls, they'd burn out in no time. It's all about making sure everything runs like a well-oiled machine – literally!

Read also:A South African Gogos Jawdropping Transformation Thats Got Everyone Talking

Types of Shaft Balls

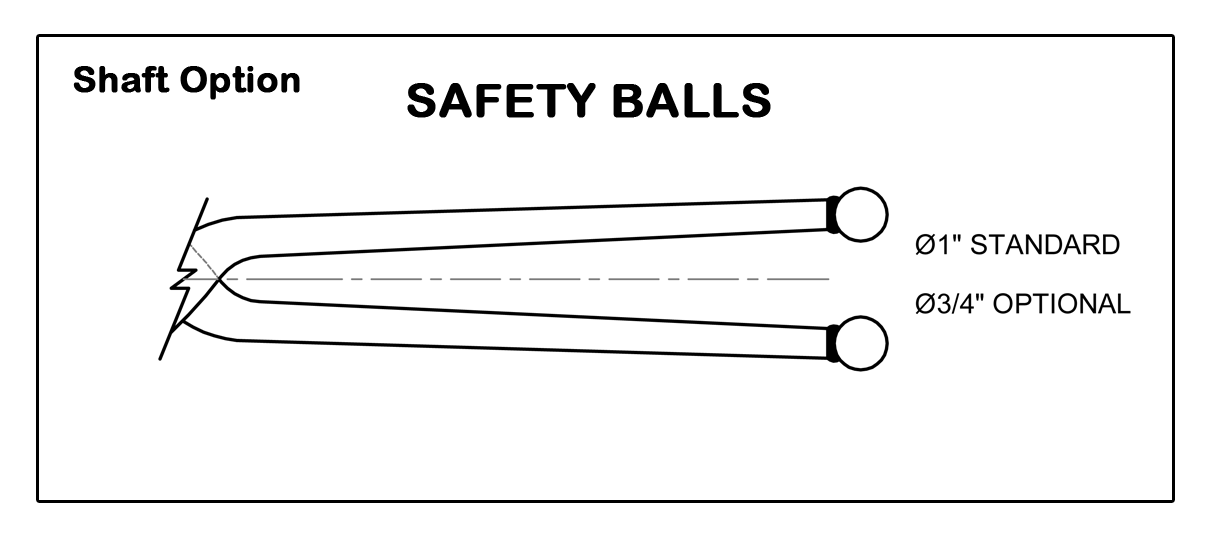

Not all shaft balls are created equal. Depending on the application, you'll find different types designed to meet specific needs. Let's take a look at some of the most common ones:

- Steel Balls: The workhorse of the bunch, steel balls are durable and can handle heavy loads.

- Ceramic Balls: Lightweight and resistant to high temperatures, ceramic balls are ideal for demanding environments.

- Plastic Balls: For lighter applications, plastic balls offer a cost-effective solution without sacrificing performance.

Choosing the Right Shaft Ball

Picking the right type of shaft ball depends on several factors, including the application, operating conditions, and budget. For instance, if you're working with heavy machinery, steel balls might be the best choice. On the other hand, if you're dealing with sensitive electronics, ceramic or plastic balls could be more appropriate. It's all about finding the right balance between performance and cost.

Installation and Maintenance Tips

Once you've got the right shaft balls, it's important to install and maintain them properly. Here are some tips to keep things running smoothly:

- Proper Alignment: Make sure the balls are aligned correctly to avoid unnecessary wear and tear.

- Regular Inspections: Keep an eye on the condition of the balls and replace them as needed. A little preventative maintenance goes a long way.

- Lubrication: Don't forget to lubricate the components regularly to minimize friction and extend their lifespan.

Common Mistakes to Avoid

When it comes to shaft balls, there are a few common mistakes that can lead to problems down the line. For example, using the wrong type of ball for the application or neglecting regular maintenance. These might seem like small oversights, but they can have big consequences. So, stay vigilant and do your homework!

Understanding the Science Behind Shaft Balls

For those of you who like to dive deeper, let's talk about the science behind shaft balls. It all boils down to material properties and design. The right combination of hardness, durability, and surface finish can make a world of difference in how well these components perform.

For instance, the surface finish of a shaft ball can greatly affect its ability to reduce friction. A smoother finish means less resistance, which translates to better performance and longer lifespan. It's all about optimizing every little detail to get the best results.

Material Science and Shaft Balls

Material science plays a huge role in the development of shaft balls. Researchers are constantly exploring new materials and manufacturing techniques to improve performance and efficiency. From advanced alloys to nanotechnology, the possibilities are endless. Who knows? Maybe one day we'll have self-lubricating balls that never need maintenance!

The Future of Shaft Balls

As technology continues to evolve, so too will the world of shaft balls. Innovations in materials and manufacturing processes are paving the way for components that are lighter, stronger, and more efficient than ever before. This means machines will run smoother, last longer, and consume less energy.

Imagine a future where shaft balls are made from smart materials that adapt to changing conditions in real-time. Sounds like science fiction, right? But with the rapid advancements in technology, it might not be too far off.

Trends in Shaft Ball Technology

Some of the current trends in shaft ball technology include the use of advanced coatings, hybrid materials, and 3D printing. These innovations are opening up new possibilities for customization and optimization, allowing manufacturers to tailor components to specific applications like never before.

Conclusion

And there you have it, folks! We've covered the basics of shaft balls, their importance, applications, and even peeked into the future of this fascinating field. Whether you're a seasoned engineer or just someone curious about how things work, understanding these components can give you a new appreciation for the machines we rely on every day.

So, what's next? If you found this article helpful, feel free to share it with your friends and colleagues. And if you have any questions or comments, drop them below. Let's keep the conversation going and continue learning together!

Table of Contents