When you think about the heart of modern manufacturing, Great Lakes Machining might not immediately pop into your mind. But trust me, this is the unsung hero behind some of the most advanced technologies we use today. From aerospace components to automotive parts, Great Lakes Machining has been quietly shaping the world as we know it. And let's face it, if precision engineering were a movie star, Great Lakes Machining would be the A-lister in the background making everything look flawless.

Now, I know what you're thinking. "Why should I care about machining?" Well, here's the deal: if you're into innovation, efficiency, or just plain cool stuff, this industry is where the magic happens. Great Lakes Machining isn't just about cutting metal; it's about creating solutions that keep industries running smoothly. And hey, who doesn't love a good story about how something seemingly ordinary can have such a massive impact?

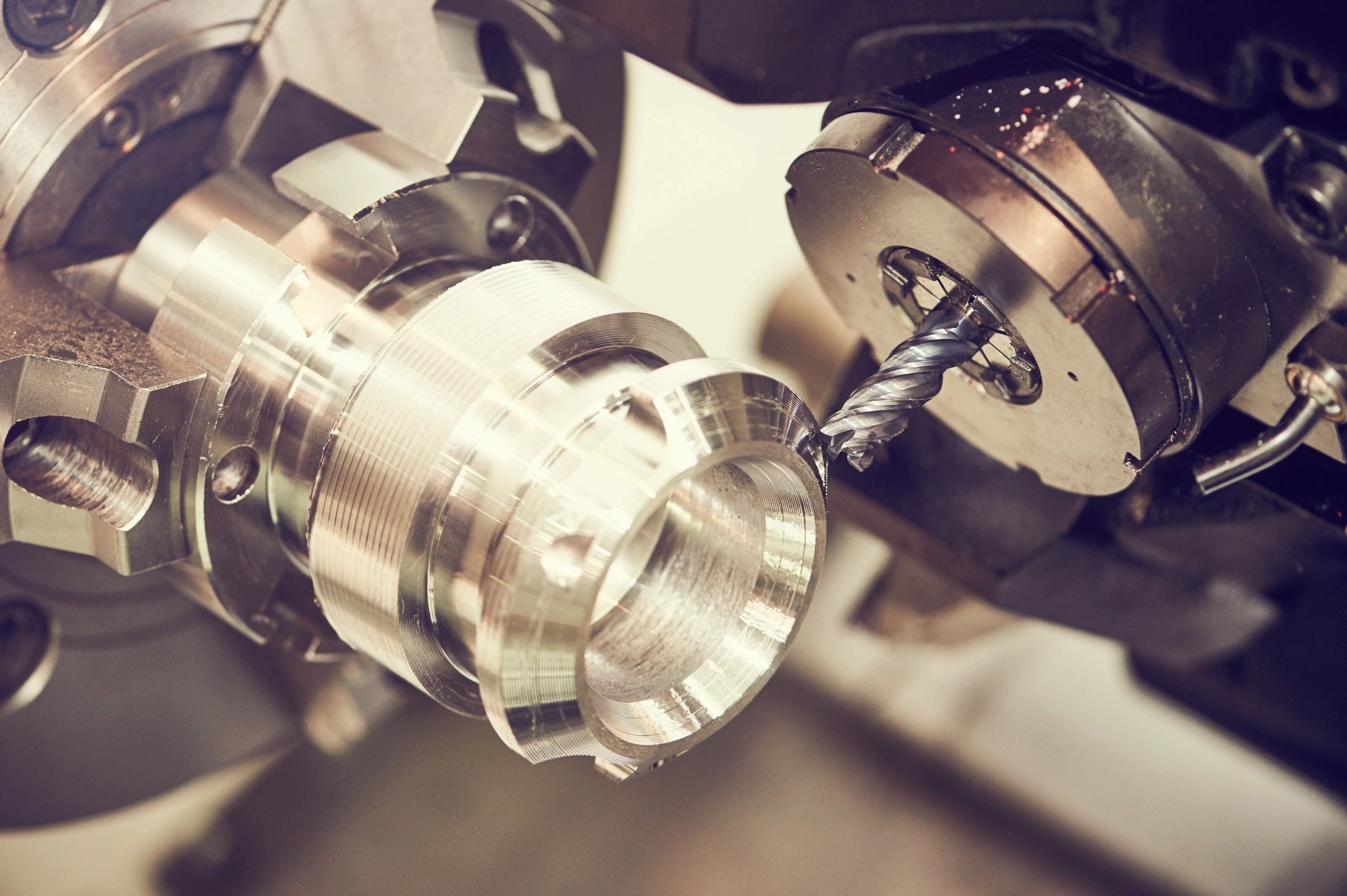

Before we dive deep into the world of Great Lakes Machining, let's set the stage. This isn't just another manufacturing process; it's a blend of art and science. Think about it like this: if the machinery is the paintbrush, then Great Lakes Machining is the artist turning raw materials into masterpieces. So, buckle up because we're about to explore why this field is so darn important and how it affects our everyday lives.

Read also:A Heartwarming Journey Back To University With Gogo

Understanding the Basics of Great Lakes Machining

Alright, let's get down to the nitty-gritty. What exactly is Great Lakes Machining? Simply put, it's the process of shaping and cutting materials using advanced tools and techniques. But it's not just about hacking away at metal; it's a highly precise and controlled operation that demands skill, expertise, and cutting-edge technology.

Great Lakes Machining operates primarily in the Midwest region, leveraging the natural resources and skilled workforce of the Great Lakes area. This region is known for its robust manufacturing legacy, and Great Lakes Machining takes full advantage of that by delivering top-notch services to industries ranging from automotive to medical.

Key Features of Great Lakes Machining

Here's what sets Great Lakes Machining apart:

- High Precision: The level of accuracy achieved is mind-blowing. We're talking tolerances in the thousandths of an inch.

- Advanced Technology: CNC machines, robotic arms, and state-of-the-art software ensure every project meets the highest standards.

- Custom Solutions: Need something specific? Great Lakes Machining can tailor their services to fit your exact requirements.

- Sustainability Focus: They're all about reducing waste and minimizing environmental impact while maintaining quality.

The Role of Great Lakes Machining in Modern Industries

Now that we've covered the basics, let's talk about why Great Lakes Machining is so crucial to modern industries. Whether you're building airplanes, designing medical devices, or creating the next big thing in tech, precision machining is a must-have. And Great Lakes Machining is at the forefront of it all.

In the aerospace sector, for instance, Great Lakes Machining ensures that every component is perfectly aligned and functional. Even the slightest deviation could spell disaster at 30,000 feet. Similarly, in the medical field, where precision is literally a matter of life and death, Great Lakes Machining delivers components that are as reliable as they are precise.

Industries Benefiting from Great Lakes Machining

Here are a few industries that rely heavily on Great Lakes Machining:

Read also:Gayton Mckenzies Reaction To The Expropriation Bill Sparks National Debate

- Aerospace: From turbine blades to cockpit components, precision is paramount.

- Automotive: Engine parts, transmission systems, and suspension components all require meticulous machining.

- Medical: Surgical instruments, implants, and diagnostic equipment demand the utmost accuracy.

- Oil and Gas: Drilling equipment and pipelines must withstand extreme conditions, making precision machining essential.

Technological Advancements in Great Lakes Machining

Technology is evolving at lightning speed, and Great Lakes Machining is right there keeping pace. The integration of cutting-edge tools and software has transformed the industry, making it faster, more efficient, and more precise than ever before.

CNC (Computer Numerical Control) machines are the backbone of modern machining. These machines use pre-programmed software to control the movement of tools, ensuring consistency and accuracy in every operation. Additive manufacturing, or 3D printing, is also making waves, allowing for the creation of complex geometries that were once impossible to achieve.

Benefits of Advanced Technology

Here's how technology is revolutionizing Great Lakes Machining:

- Increased Efficiency: Machines can run 24/7 without fatigue, boosting productivity.

- Improved Accuracy: Automation reduces human error, ensuring consistent quality.

- Cost Savings: Less material waste and faster production times translate to lower costs.

Challenges Faced by Great Lakes Machining

Of course, no industry is without its challenges, and Great Lakes Machining is no exception. One of the biggest hurdles is keeping up with rapid technological advancements. As new tools and techniques emerge, companies must invest in training and equipment to stay competitive.

Another challenge is the skilled labor shortage. Machining requires a high level of expertise, and finding qualified workers can be tough. That's why many companies are partnering with educational institutions to develop the workforce of tomorrow.

Solutions to Overcome Challenges

Here are some strategies being employed to tackle these issues:

- Training Programs: Collaborations with schools and vocational programs are helping bridge the skills gap.

- Investment in Automation: By automating repetitive tasks, companies can focus their skilled workers on more complex projects.

- Continuous Learning: Encouraging employees to stay updated with the latest technologies and techniques.

The Future of Great Lakes Machining

Looking ahead, the future of Great Lakes Machining is bright. With advancements in AI, IoT (Internet of Things), and robotics, the possibilities are endless. Imagine machines that can predict maintenance needs before a breakdown occurs or robots that can perform tasks with human-like dexterity. These innovations are not just dreams; they're becoming a reality.

Moreover, the push for sustainability is driving the development of eco-friendly machining processes. Companies are exploring ways to reduce energy consumption, minimize waste, and recycle materials. This not only benefits the environment but also appeals to consumers who are increasingly conscious of their carbon footprint.

Emerging Trends in Great Lakes Machining

Here are a few trends shaping the future of Great Lakes Machining:

- Smart Factories: Facilities equipped with sensors and data analytics for real-time monitoring and optimization.

- Green Machining: Practices that reduce environmental impact while maintaining efficiency.

- Customization: Increased demand for personalized products driving the need for flexible machining solutions.

Great Lakes Machining: A Competitive Advantage

So, why should you choose Great Lakes Machining over other options? It all comes down to expertise, authority, and trustworthiness. The region's long history of manufacturing excellence, combined with a skilled workforce and access to cutting-edge technology, makes Great Lakes Machining a leader in the field.

Companies that partner with Great Lakes Machining gain a competitive edge through superior quality, faster delivery times, and innovative solutions. Whether you're a small startup or a global conglomerate, Great Lakes Machining can provide the precision and reliability you need to succeed.

Building Trust and Authority

Trust is built on a foundation of reliability, transparency, and consistent performance. Great Lakes Machining has earned its reputation by delivering exceptional results time and time again. Their commitment to quality and customer satisfaction sets them apart from the competition.

Conclusion: Why Great Lakes Machining Matters

To sum it up, Great Lakes Machining is more than just a manufacturing process; it's a driving force behind innovation and progress. From aerospace to healthcare, the impact of precision machining is felt across countless industries. And with the rapid pace of technological advancement, the future looks brighter than ever.

So, what can you do? If you're in need of machining services, consider partnering with Great Lakes Machining. If you're curious about the industry, keep learning and stay updated on the latest trends. And don't forget to share this article with your network. Who knows? You might just inspire someone to explore the fascinating world of Great Lakes Machining.

Table of Contents

- Understanding the Basics of Great Lakes Machining

- The Role of Great Lakes Machining in Modern Industries

- Technological Advancements in Great Lakes Machining

- Challenges Faced by Great Lakes Machining

- The Future of Great Lakes Machining

- Great Lakes Machining: A Competitive Advantage

- Conclusion: Why Great Lakes Machining Matters

And there you have it! A deep dive into the world of Great Lakes Machining. Remember, precision isn't just a buzzword; it's the backbone of modern manufacturing. So, whether you're a tech enthusiast, a business owner, or just someone who appreciates how things work, Great Lakes Machining is definitely worth exploring.